With snow being forecast, I thought I had better visit the stockist before the weekend. (Not that I really need an excuse - it's always exciting.) You never know what piece of glass will catch your eye. That's what makes it so dangerous. The list is essential.

I noticed that I wasn't the only person with a list.

'If I don't have one, I'm bound to forget something.'

My problem tends to be 'if I don't have one, I'm bound to come away with something that I hadn't intended'.

I admired a piece of glass that was destined for a window.

Someone else had a computer - generated image in hand. A painstaking search was being conducted amongst the racks of opalescent glass to find the 'perfect' shade to match the project.

Me? I had a list and a cartoon of the panel to be constructed with me. Thank goodness this was going to be in clear glass, not so many decisions. Although the choice was narrowed considerably, I did have to decide on the texture. Then there was which piece of glass? It's amazing how each piece varies so considerably. I held each piece against the light so all the features of it were visible and eventually made my choices.

I wanted an opulent look to the panel, so I made my way to the 'bevel' section. I tried two or three kinds on my cartoon. A circular bevel would be the best bet. These were only available in one size. I considered the 'roundels'. (Too large) What about 'globs'? I went to the 'glob' section. There were varying sizes and colours - and I found clear globs in differing sizes. I placed some of these on the cartoon - much better. They would give the look I was after. How many? I shifted the globs around the cartoon.

Back to the list. Lead and cement were the only other items. I was very good. I only gave the racks of coloured glass the briefest of looks. Only too soon, with my purchases carefully wedged in the car, was I making my return journey. Hopefully it wouldn't be too long before I would be revisiting the supplier.

Saturday 22 November 2008

Thursday 20 November 2008

Curvy

It is always good to start with a clean sheet - paper. It's a new beginning. Like all new beginnings it can be exciting and somewhat daunting.

No different, then, in starting a new design for a window.

I've decided on something abstract, something new. There are lots of ideas in pattern books. I've decided against something symmetrical. A mixture of standard grid with luxurious and generous curves.

All the glass will be clear. The background will be cut from a curvaceous baroque glass. Shapes will be made from a variety of textured glass. Long lead lines will attract the eye and draw it along the curves.

I've decided upon the lead thickness. The only thing left to consider is the inclusion, or not, of bevels or jewels, and the amount of materials needed.

It's all drawn out.

A visit to the stockist is required.

Oh dear!

Always dangerous.

Perhaps I ought to make a list.

No different, then, in starting a new design for a window.

I've decided on something abstract, something new. There are lots of ideas in pattern books. I've decided against something symmetrical. A mixture of standard grid with luxurious and generous curves.

All the glass will be clear. The background will be cut from a curvaceous baroque glass. Shapes will be made from a variety of textured glass. Long lead lines will attract the eye and draw it along the curves.

I've decided upon the lead thickness. The only thing left to consider is the inclusion, or not, of bevels or jewels, and the amount of materials needed.

It's all drawn out.

A visit to the stockist is required.

Oh dear!

Always dangerous.

Perhaps I ought to make a list.

Saturday 15 November 2008

Functional art

Back to the workbench again.

Total relaxation. Just the third and final panel to assemble and solder. I left the most complicated part of the design to the last panel. Only one piece of internal lead was to be 1/4", the rest was to be 3/16". It all went together quite quickly.

I arranged the four panels on the bench. The leads undulated from left to right. Lead came of similar sizes followed on from one another. They worked well together.

We held the panels up to the artificial light, as the natural light outside had dimmed somewhat.

It was going to look good!

Total relaxation. Just the third and final panel to assemble and solder. I left the most complicated part of the design to the last panel. Only one piece of internal lead was to be 1/4", the rest was to be 3/16". It all went together quite quickly.

I arranged the four panels on the bench. The leads undulated from left to right. Lead came of similar sizes followed on from one another. They worked well together.

We held the panels up to the artificial light, as the natural light outside had dimmed somewhat.

It was going to look good!

Thursday 13 November 2008

Small Panels

I had another session with the small panels today.

The second panel only needed the last two sides of the perimeter to be leaded. Very quickly the lead was cut and the coloured glass was persuaded into the channel. Onto the soldering. Very little to do since there were not many pieces. Unplug the iron.

I put the two soldered pieces on the workbench, arranged as they would be viewed in situ. Leaded curves of varying thickness meandered as designed.

Better make a start on the next. Which thicknesses of lead are required this time? Check the pattern. 3/16" and 1/4" for the internal leading. (Yes - still in imperial) At least one real life example of why fractions should be understood... at last I've found it! Yes, 1/16" does make quite a noticeable difference! Having spent the largest portion of one's life measuring in centimetres, it does seem strange reverting to imperial. But then, it is an old craft.

The second panel only needed the last two sides of the perimeter to be leaded. Very quickly the lead was cut and the coloured glass was persuaded into the channel. Onto the soldering. Very little to do since there were not many pieces. Unplug the iron.

I put the two soldered pieces on the workbench, arranged as they would be viewed in situ. Leaded curves of varying thickness meandered as designed.

Better make a start on the next. Which thicknesses of lead are required this time? Check the pattern. 3/16" and 1/4" for the internal leading. (Yes - still in imperial) At least one real life example of why fractions should be understood... at last I've found it! Yes, 1/16" does make quite a noticeable difference! Having spent the largest portion of one's life measuring in centimetres, it does seem strange reverting to imperial. But then, it is an old craft.

Wednesday 12 November 2008

Cleaning Up

Each panel on both sides of the glass needed tidying, removing the excess cement. An easy job. Cleaning the lead came required the donning of gloves. Next, attaching metal ties that would further strengthen the panel - was not quite so easy. I always feel an extra pair of hands would be useful at this point, as the metal always seems to wriggle out of place when solder is applied.

Lead darkening next. Lead darkens naturally over time, but not everyone wants a bright, new finish and is prepared for nature to take its course.

Further cleaning. The glass this time. Get rid of the smears... make it look squeaky clean.

Time for a photo call. So different from when it arrived, broken and forlorn. Now it looked bright, strong and proud, ready for service for the next few decades.

Lead darkening next. Lead darkens naturally over time, but not everyone wants a bright, new finish and is prepared for nature to take its course.

Further cleaning. The glass this time. Get rid of the smears... make it look squeaky clean.

Time for a photo call. So different from when it arrived, broken and forlorn. Now it looked bright, strong and proud, ready for service for the next few decades.

A Change of Scene

I thought I'd ring the changes yesterday, and work on something else. Four small panels to replace some clear, bullseye glass.

I'd already cut out the glass, so only the soldering iron would be pressed into action. Thankfully the workbench was all clean, and I had laid out the pieces.

Although only small, these panels still required the attention and care of the previous panel as they were bound for a domestic setting.

Starting, as usual, was the tricky bit - setting up the jig, preparing the lead and positioning the design in the correct place. It was fairly plain sailing after the first piece had been placed. I had cut the pieces accurately and they slotted in like a dream.

I used up my spare lead first - it's a very expensive commodity at the moment. Some suppliers are not even publishing the prices in their brochures - the customer having to phone to find the latest prices - such has been the latest price hikes. (Not their fault)

The lead was an important part of this design, different widths following curves that linked all four panels to create a unified artform. Not able to resist, once soldered, I held up the small piece against the natural light. Although grey outside, the glass came to life in a glorious glow of vibrant colour.

It gave a warm feeling, far removed from the temperature and scene outside.

I'd already cut out the glass, so only the soldering iron would be pressed into action. Thankfully the workbench was all clean, and I had laid out the pieces.

Although only small, these panels still required the attention and care of the previous panel as they were bound for a domestic setting.

Starting, as usual, was the tricky bit - setting up the jig, preparing the lead and positioning the design in the correct place. It was fairly plain sailing after the first piece had been placed. I had cut the pieces accurately and they slotted in like a dream.

I used up my spare lead first - it's a very expensive commodity at the moment. Some suppliers are not even publishing the prices in their brochures - the customer having to phone to find the latest prices - such has been the latest price hikes. (Not their fault)

The lead was an important part of this design, different widths following curves that linked all four panels to create a unified artform. Not able to resist, once soldered, I held up the small piece against the natural light. Although grey outside, the glass came to life in a glorious glow of vibrant colour.

It gave a warm feeling, far removed from the temperature and scene outside.

Tuesday 11 November 2008

Flux

With the all clear to proceed, it was on with the soldering and the application of flux. Just a very short while to wait until the bright, shiny tip of the iron was at the required temperature to do its job.

Quite a few joints needed soldering. Neat soldering was the order of the day, as the piece of glass would be situated in a place affording close scrutiny. (Unlike church glass which is viewed and admired from afar.) Once the first side was complete, careful handling would be required to turn the glass to its reverse side for soldering.

The messy bit next. It always seems to take much longer than anticipated, but both sides were soon completed. At last the glass resembled what I had imagined the original had once looked like. All bright with long lengths of straight lead came.

A photo opportunity - get the camera out!

Quite a few joints needed soldering. Neat soldering was the order of the day, as the piece of glass would be situated in a place affording close scrutiny. (Unlike church glass which is viewed and admired from afar.) Once the first side was complete, careful handling would be required to turn the glass to its reverse side for soldering.

The messy bit next. It always seems to take much longer than anticipated, but both sides were soon completed. At last the glass resembled what I had imagined the original had once looked like. All bright with long lengths of straight lead came.

A photo opportunity - get the camera out!

Saturday 8 November 2008

A new Skeleton

Starting is always tricky... whether it's writing the first paragraph of an essay, counting out a piece of cross-stitch or indeed starting to assemble a leaded light. All the more so when the finished size is predetermined as it's replacing an old piece, and it's got to fit a hole.

The pattern, I knew was unreliable as it had been drawn using the broken and twisted form of the old piece of glass. The new glass was accurate to the millimetre. Two sides of the perimeter were positioned and the first numbered glass was slotted into place. The pattern was a good half an inch out - oh dear! After much fiddling with the pattern and measuring I was satisfied that I could position the next three pieces. Why couldn't they be a simple rectangle? It was obvious that the pattern was going to be 'out' during the whole assembly.

Quite quickly the glass took shape.

The last section was not going to be easy. Utilising the old glass, odd shaped new pieces and curves... lots of them. What was more, because of the design, some pieces of glass would have to be fitted at the same time, as pieces fitted snugly inside others. A bit of thought was going to be required as to how this was to be achieved. I still didn't know if the leaded light would be the desired size. Only when the other two pieces of perimeter lead were in place would I know.

The last pieces are tricky too!

Finally, the body had its new skeleton.

The pattern, I knew was unreliable as it had been drawn using the broken and twisted form of the old piece of glass. The new glass was accurate to the millimetre. Two sides of the perimeter were positioned and the first numbered glass was slotted into place. The pattern was a good half an inch out - oh dear! After much fiddling with the pattern and measuring I was satisfied that I could position the next three pieces. Why couldn't they be a simple rectangle? It was obvious that the pattern was going to be 'out' during the whole assembly.

Quite quickly the glass took shape.

The last section was not going to be easy. Utilising the old glass, odd shaped new pieces and curves... lots of them. What was more, because of the design, some pieces of glass would have to be fitted at the same time, as pieces fitted snugly inside others. A bit of thought was going to be required as to how this was to be achieved. I still didn't know if the leaded light would be the desired size. Only when the other two pieces of perimeter lead were in place would I know.

The last pieces are tricky too!

Finally, the body had its new skeleton.

Thursday 6 November 2008

A New Body

Where to start? The trickiest parts first. The difficult cuts.

- Take an old piece of glass

- Scrape off the excess cement

- Draw round it to make a paper pattern

- Draw round the pattern onto a new piece of glass

- Cut out the glass - a new piece of glass the same size and shape as the old piece

So, where to start? With the concave curves, then with the thin tapering points . Get those pieces out of the way. Then the easier pieces - the rectangles. Are they all numbered?

So far so good. Now for the pieces of glass that have to be salvaged, scraping off the old cement.

A first glimpse of what the final piece will look like - on placing all the glass in the correct places, ready for assembly.

The body is ready for its skeleton.

Enough for today.

Tuesday 4 November 2008

Disintegrating

The 'patient' was relocated.

Separation of salvagable glass from the broken, and wrestling it free from its confines in the lead, took the best part of the afternoon.

Where to cut? Where to prise apart? Trying not to break the glass. One piece bit the dust - it simply wasn't possible to save it, especially with its particular shape. Trying to conserve connecting pieces of lead so the type of joint could be studied and emulated. Much of it looked like a motorway junction.

From the more intricate glass shapes it could be discerned that the glass had been cut and shaped before the advent of the more advanced tools of today.

Finally the 'flesh' was separated from its 'skeleton'. Whilst the glass (which had been salvaged)

lay on the bench, the old lead came was respectfully laid to rest on a cardboarded floor.

The light was switched off.

Separation of salvagable glass from the broken, and wrestling it free from its confines in the lead, took the best part of the afternoon.

Where to cut? Where to prise apart? Trying not to break the glass. One piece bit the dust - it simply wasn't possible to save it, especially with its particular shape. Trying to conserve connecting pieces of lead so the type of joint could be studied and emulated. Much of it looked like a motorway junction.

From the more intricate glass shapes it could be discerned that the glass had been cut and shaped before the advent of the more advanced tools of today.

Finally the 'flesh' was separated from its 'skeleton'. Whilst the glass (which had been salvaged)

lay on the bench, the old lead came was respectfully laid to rest on a cardboarded floor.

The light was switched off.

Monday 3 November 2008

Skeleton

I'll have to get the camera swinging into action. I've got a corpse - well not actually a corpse, but a very unhappy piece of glass work has found its way to my door.

Another errand... a chance meeting... a question... and word of mouth.

Like all detectives, I thought I had better follow it up - strike while the iron was hot, so to speak.

There it lay, a broken and twisted skeleton, strapped to a board like a patient on a stretcher. Far removed from its place of pride, it looked forlorn.

Get the camera going. Take photos. Before and after, like the make-over features in magazines. Take measurements. It's got to be the right dimensions if it's to rejoin its companion.

Better get started.

Another errand... a chance meeting... a question... and word of mouth.

Like all detectives, I thought I had better follow it up - strike while the iron was hot, so to speak.

There it lay, a broken and twisted skeleton, strapped to a board like a patient on a stretcher. Far removed from its place of pride, it looked forlorn.

Get the camera going. Take photos. Before and after, like the make-over features in magazines. Take measurements. It's got to be the right dimensions if it's to rejoin its companion.

Better get started.

Friday 31 October 2008

An appreciation of the visual arts

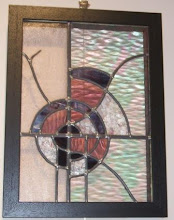

It always gives you a lovely warm glow when your work is appreciated - especially if the piece you are designing and making is for someone you know.

The design has been agreed - the glass chosen. In many ways the most difficult part of the process has been achieved. That just leaves the making. It's really good as each piece is cut out and assembled to ponder, 'Where in their house will it go?' The nature of the glass has already dictated whether the piece is wall - bound or destined for a windowsill where light can stream through.

The artwork was duly delivered and placed carefully.

'Wow....' was the unsolicited response, as vivid colours met the gaze of the observer.

I was overwhelmed when the observer rushed off and came back to present me with a sticker... the seal of approval. The observer stood before the artwork once more to make sense of it.

'It's got an eye..... and ears

.....and ....... bogies.'

The new owners saw a Mackintosh - inspired piece. The young observer saw something quite human.

I hope everyone enjoys the piece for many years to come - putting their own interpretation on what they see.

The design has been agreed - the glass chosen. In many ways the most difficult part of the process has been achieved. That just leaves the making. It's really good as each piece is cut out and assembled to ponder, 'Where in their house will it go?' The nature of the glass has already dictated whether the piece is wall - bound or destined for a windowsill where light can stream through.

The artwork was duly delivered and placed carefully.

'Wow....' was the unsolicited response, as vivid colours met the gaze of the observer.

I was overwhelmed when the observer rushed off and came back to present me with a sticker... the seal of approval. The observer stood before the artwork once more to make sense of it.

'It's got an eye..... and ears

.....and ....... bogies.'

The new owners saw a Mackintosh - inspired piece. The young observer saw something quite human.

I hope everyone enjoys the piece for many years to come - putting their own interpretation on what they see.

Subscribe to:

Posts (Atom)