With the all clear to proceed, it was on with the soldering and the application of flux. Just a very short while to wait until the bright, shiny tip of the iron was at the required temperature to do its job.

Quite a few joints needed soldering. Neat soldering was the order of the day, as the piece of glass would be situated in a place affording close scrutiny. (Unlike church glass which is viewed and admired from afar.) Once the first side was complete, careful handling would be required to turn the glass to its reverse side for soldering.

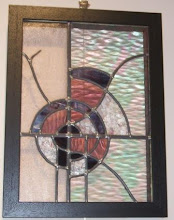

The messy bit next. It always seems to take much longer than anticipated, but both sides were soon completed. At last the glass resembled what I had imagined the original had once looked like. All bright with long lengths of straight lead came.

A photo opportunity - get the camera out!

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment